Imikhiqizo

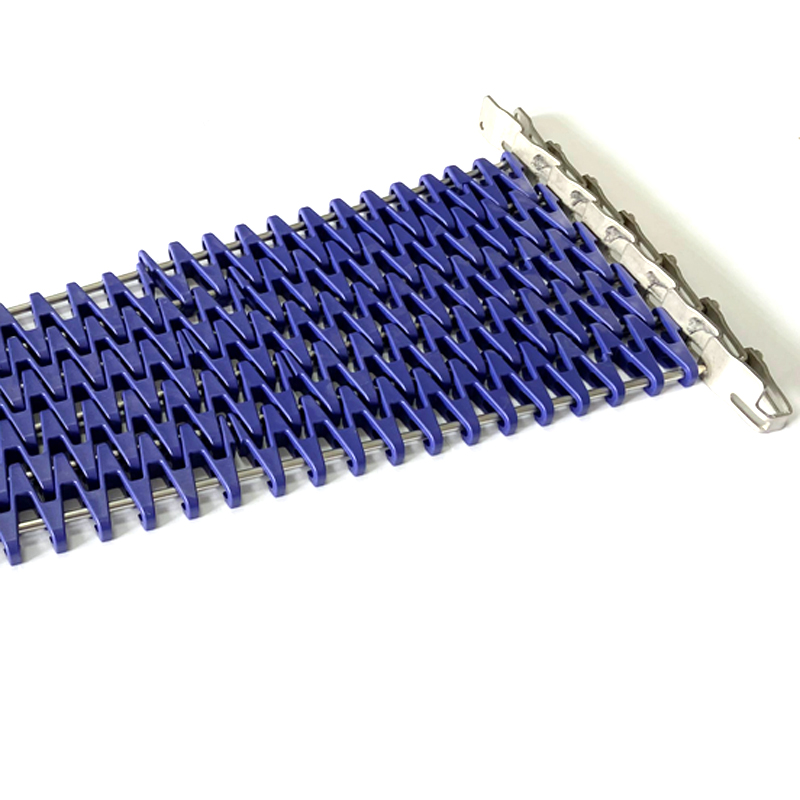

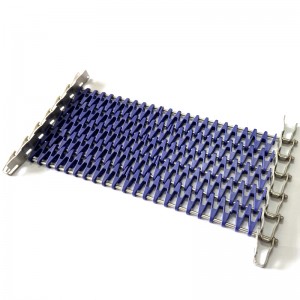

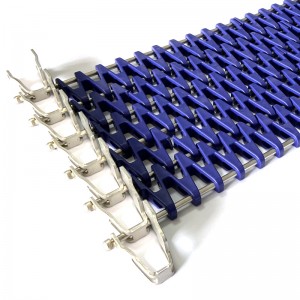

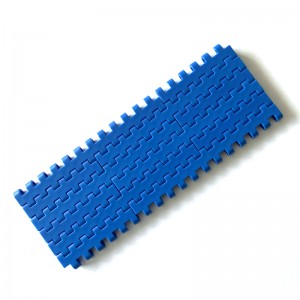

I-HAASBELTS Conveyor U193 Spiralox Flush Grid

Imingcele ye-Sprocket

| Uhlobo lwe-Sprocket | Inani lamazinyo | I-pitch diameter | Ububanzi bangaphandle | A1 | Bore |

| H (mm) | C (mm) | mm | I-DF (mm) | ||

| 1-U193-17-40R | 17 | 207.4 | 215.8 | 98.0 | φ40 |

| 1-U193-17-50R | φ50 | ||||

| 1-U193-17-60R | φ60 |

Ukugcinwa nokugcinwa kwe-spiral mesh belt conveyor

Ukuhlola okuvamile: Hlola njalo zonke izingxenye ze-spiral mesh belt conveyor, okuhlanganisa ama-bhering, amaketango, amabhande anezikhala, njll., ukuze uhlole ukuguga, ukuxega, noma ukungasebenzi kahle.Ikakhulukazi amabhande anezikhala, ukungcola okunamathiselwe kuwo kufanele kuhlanzwe njalo ukuze kugwenywe ukuthikameza ukusebenza kwawo okuvamile.

Ukuthambisa: Gcoba njalo ama-bearings namaketango okuhambisa ibhande le-spiral mesh ukuze unciphise ukungqubuzana nokuguga.Ngama-bearings, amafutha okugcoba angangezwa njalo, futhi inani eliphelele lomjovo lingabhekisela ku-2/3 yesikhala sangaphakathi sebhokisi elithwala;Gcoba amabheringi okulengiswa kanye namashafu kugrisi wokugcoba njalo ngezikhathi ezi-4.

Ukuhlanza: Gcina i-spiral mesh belt conveyor ihlanzekile ukuvikela ukungcola nokungcola ukuthi kungangeni.Phakathi nenqubo yokudlulisa, izinto ezinkulu noma izinto zensimbi ezintweni kufanele zigwenywe ukuthi zingangeni ku-conveyor ukuze kugwenywe ukulimala kwempahla.

Ukuqiniswa: Hlola njalo ukuqiniswa kwezingxenye ezihlukahlukene ze-spiral mesh belt conveyor, futhi uziqinise ngesikhathi esifanele uma kukhona ukuxega kutholakala.

Ukugcinwa kwedivayisi yokushayela: Ukugcinwa njalo kwedivayisi yokushayela yesidluliseli sebhande elivunguzayo, okuhlanganisa nokuhlola ukusebenza kwe-drive motor kanye ne-reducer, kanye nokuhlola ukushuba nokuthambisa kweketango lokushayela.

Ukulungiswa kokuvala shaqa: Ngemva kokuvala shaqa isikhathi eside, kuyadingeka ukusebenzisa umshini ngaphandle komthwalo isikhathi esithile ukuze uqinisekise ukuthi zonke izingxenye zisebenza kahle ngaphambi kokwenza umsebenzi wokulayisha.Ngaphambi kokumisa umshini, zonke izinto ezingaphakathi kweconveyor kufanele zidluliselwe ukuze kugwenywe umonakalo odalwe yizinto ezishiywe ku-conveyor isikhathi eside.

Ukunakekela okuvikelayo: Yenza uhlelo olujwayelekile lokuvikela lokuvikela, okuhlanganisa ukuhlolwa okuvamile, ukugcotshwa, ukuhlanzwa, njll., ukuvimbela ukwehluleka ukwehluleka ukwenzeka.Uma noma yimuphi umsindo noma ukudlidliza okungavamile kutholakala empahleni, kufanele imiswe ngokushesha ukuze ihlolwe futhi kuxazululwe izinkinga.

Ngokulandela izinyathelo zokulungisa ezingenhla, impilo yesevisi kanye nokusebenza komthumeli webhande le-spiral mesh kungathuthukiswa ngempumelelo, futhi ukuvela kwamaphutha kungancishiswa.

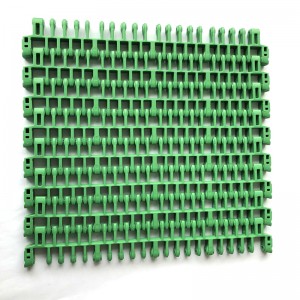

Inqubo yokwenza ngendlela oyifisayo amabhande epulasitiki anezikhala

Yakha futhi uklame izinhlelo zokukhiqiza ezinemininingwane esekelwe ezidingweni zamakhasimende kanye nezidingo zemishini ethile.

Yenza isikhunta, khetha izinto zepulasitiki ezifanele, futhi ujove amamojula epulasitiki ngokusebenzisa imishini yokubumba ehambisanayo.

Hlukanisa ngokuvumelana nobubanzi nobude bekhasimende ukuze wakhe ibhande le-plastic mesh modular.

IZIGABA ZOMKHIQIZO

Gxila ekunikezeni izixazululo ze-mong pu iminyaka emi-5.